Fun and games for final week of Elements

The final week of Semester 1’s 3D Product Design Elements course produced some fantastic 3D printed chess pieces and laser engraved chess boards. Tasked with designing in Bauhaus style, the students have risen to the challenge of designing on industry standard CAD software to produce high quality CAM manufactured outcomes Well done!

Pallet upcycling project

This semester’s 3D Product designers were asked to make bat boxes for several of the ESF primary schools and an art installation for IS using upcycled materials. Students learned and applied some traditional carpentry skills to produce their boxes and signs and reduced the need to “buy new” through their use of upcycled pallets.

Mr P’s wild Woodshop

Elements 3D designers were busy bees today, stepping back in time to develop some traditional woodworking and joinery skills. Haruka has produced a fantastic hardwood desk tidy, whilst the boys got to grips with drills and screws to put the final structural touches on previous semester’ 50th anniversary Picnic table!

3D Product Designers work with CAD/CAM

This semester’s 3D Product design students have been learning how to design and manufacture products using CAD/CAM technologies. From 3D printed phone cases to CNC machined desk tidies and speakers, students have demonstrated their capacity to learn modern manufacturing techniques whilst following a modern minimalist design brief.

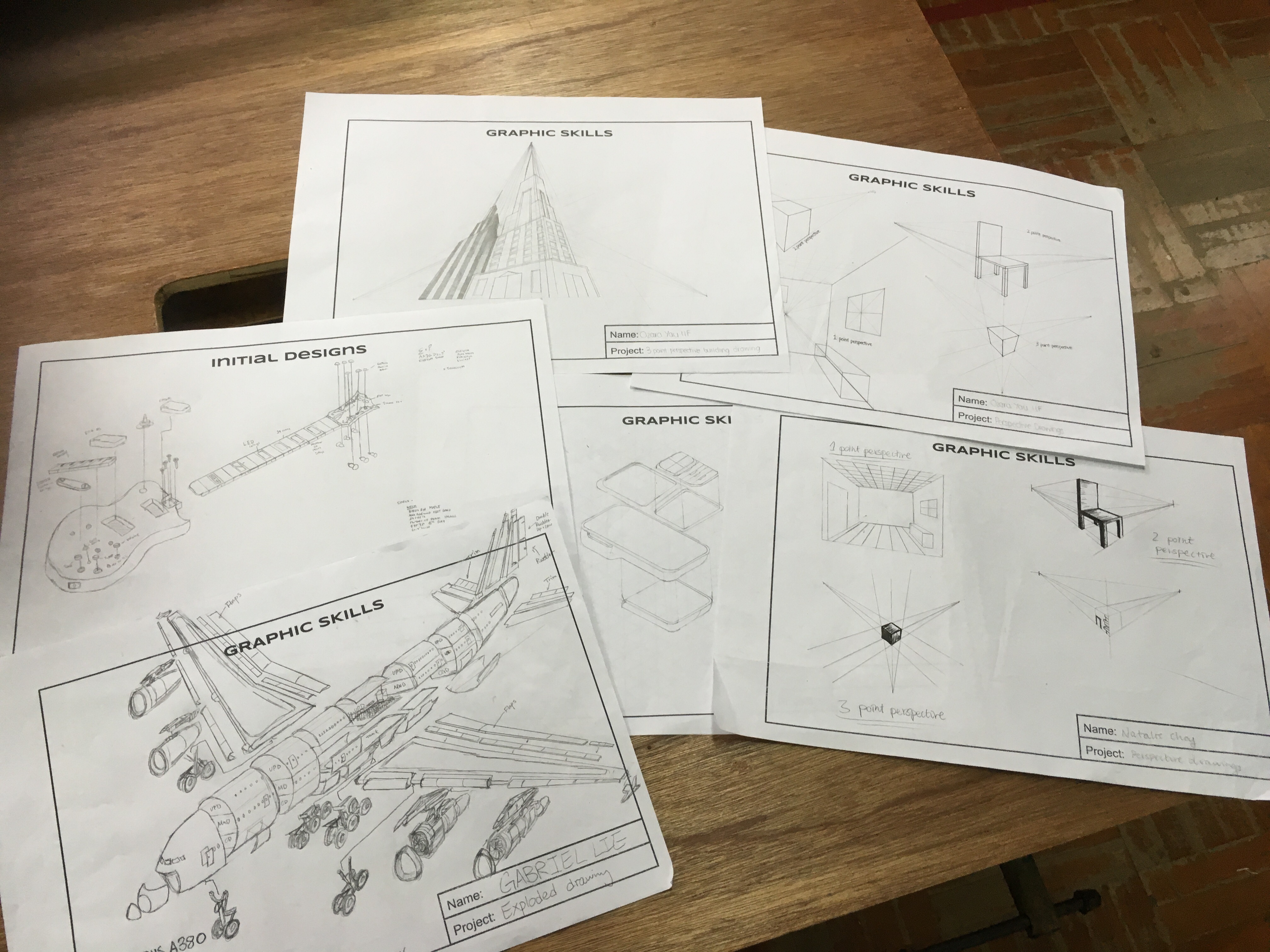

Getting to grips with Graphic skills

Students in this semester’s 3D Product Design elements course learn the basics of being a designer – how to draw!

The fundamental communication tool of the designer, knowing how to draw is an important characteristic of becoming a designer. Students have learned how to draw:

Oblique, Isometric, 1,2 and 3 point perspective and exploded drawings.

Next week: Rendering!

Designers of the week – “Pointing” in the right direction…

Ann and Anna (Y10) of the 3D Product Design Elements class took on a nautical theme this week in the “Speed Innovation Challenge”. Students were tasked with designing an making an innovative product from a set list of materials, with only 3 hours to brainstorm, design, develop and manufacture!

All outcomes were impressive given the time and resource restrictions, with two designers, Ann He (10E) and Anna Choi (10W), sailing away with the most intricate design. They produced an ornamental, nautical compass from only two of their available resources (sustainable minds?) and applied some advanced metalworking skills (on the metal working lathe) to engineer precise fittings for their compass.

Each pair will be applying their best sales tactics to try and persuade the remainder of the class to invest in their product, based on their competitive marketing strategies. Will it be sink or swim for the designers of the week? Find out next week!

Defying Gravity – Happy Chinese New Year!

Parents of our new set of creative designers in 3D Product Design Elements course will be pleased to see what might be coming their way this CNY with some gravity defying wine bottle holders!

This CNY themed design was made by Jasmine Chan in 10E. Well done on a great seasonal design!

Other great designs featured are: Jaimie Vine, Lewis Ng and Charlotte Donoghue.

Mong Kok jewellers have some competition!

It’s the final week of this semester’s 3D Product Design entrepreneur challenge, and things are blinging up!

This week’s highlight is Jess Gdowski and Simran Katvi’s bespoke jewellery. Having acquired CAD, CAM and metalworking skills during a previous project, they have applied these skills to design laser cut MDF moulds, which were then used to produce pewter jewellery, via pewter casting.

Post-cast finishing is currently taking place with some hand files, before polishing takes place with the buffing machine.

3D Product Design – Elephant in the room

The 3D Product Design elements groups are working at full steam in finalising their designs for the entrepreneurial challenge.

This week sees some elephant phone/tablet holders made from acrylic. Having spent a long time modelling their initial designs in styrofoam, the group (Anna, Chloe and Kaori) have gone down an alternative route to make a simplified version of their initial holder design, by firing them in the oven!

The most recent iteration of design focuses on heating acrylic sheet until malleable, then forming it around an MDF elephant shaped former. After 1 minute of frantically clamping, the finished design resembles a baby elephant, which doubles as a phone/tablet holder.